Inside Toyo Ink Europe: Custom Colour Mixing

Behind every custom colour lies a careful balance of science, experience, and collaboration. Matching a colour is about truly understanding how colours and inks behave under real printing conditions. At Toyo Ink Europe, our colour mixing specialists work closely with customers, to ensure that every custom colour meets both visual expectations and technical requirements. In this edition of Inside Toyo Ink Europe, we take a closer look at how a custom colour is created, from the initial request to final production.

From Customer Request to Colour Definition

Most custom colour orders begin with a Pantone (PMS) reference, a printed or wet sample or L*a*b* values provided by the customer. Although this reference defines the target colour, it is only the beginning of the process. To achieve an accurate match, our team first determines which ink series the customer is using: is it an offset or flexo series? Each series has its own characteristics, which directly influence how a colour is reproduced during printing.

If the customer has additional requirements, such as low migration, increased resistance to light, chemicals or other functional properties, these are included immediately. By incorporating these parameters from the start, we ensure that the colour is achieved using inks that meet both aesthetic and performance demands.

The substrate is just as important as the properties of the ink. The same colour and ink can appear very different depending on the material they are printed on, whether it is coated or uncoated, and how it is treated after printing. That is why we always want to define the substrate upfront with the customer to provide a colour that matches perfectly.

Creating the Colour in the System

Once all parameters have been defined, the target colour is entered into our colour formulation system. Using our extensive ink database, the system calculates an initial colour formula based on the selected ink series, the final substrate, the available base inks and the required ink properties. This calculated recipe is not a generic approximation, but a formulation specifically tailored to the customer’s application. It provides a precise starting point that allows our colour specialists to work efficiently while maintaining a high level of accuracy.

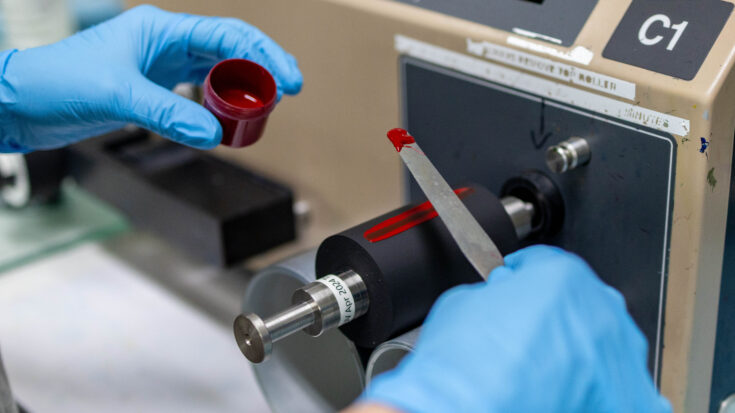

Once the initial formula has been established, a small amount of ink is carefully mixed according to the calculated recipe. This ink is then printed as a proof on the specified substrate. Printing a proof is a critical step, as it reveals how the colour behaves under real production conditions rather than solely in theoretical calculations. Seeing the colour on the actual substrate allows our team to evaluate not only the numerical accuracy, but also the visual appearance of the colour in its intended context.

Measuring, Correcting, and Perfecting

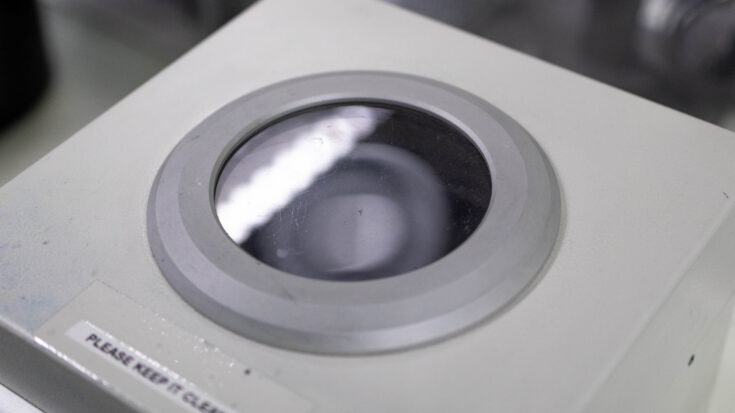

After printing, the proof is measured using colour measurement equipment to determine its ‘Lab’ values, represented as L* (lightness), a* (green-red spectrum), and b* (blue-yellow spectrum). These measured values are compared to the target colour, if the result falls within the acceptable tolerance, the colour is approved and ready for production.

In case the colour does not meet the accuracy requirements, the process continues. Based on the measured result, the formulation is corrected and a new recipe is generated. The inks are then mixed, printed, and measured again. This iterative process ensures that even the smallest deviations are corrected, that is resulting in colour that is accurate both visually and digitally.

From Approved Formula to Final Production

Once the colour has been approved, the validated formulation is used to produce the final ink for the customer. As the colour has been tested and adjusted on the appropriate substrate and in the appropriate ink series, the customer can count on consistent results throughout their own production process.

Custom colour mixing is not a standalone activity. It is a collaborative effort that brings together colour specialists and customer feedback. By combining advanced colour measurements, substrate-specific testing, and expert knowledge, Toyo Ink Europe ensures that every custom colour reflects the same level of precision and care as our standard products.

Every custom colour tells a story: one of attention to detail, technical expertise, and a shared commitment to providing exactly what the customer needs, every time.

Latest news

Toyo Ink Europe completed German Ink Ordinance compliant ink portfolio in 2025

Toyo Ink Europe, the European-based energy-curing inks division of artience Group, Japan, marked 2025 with a major expansion of its GIO-compliant ink portfolio.

Toyo Ink Europe sets its R&D direction for 2026

Marc Heylen, General Manager Technology, explains Toyo Ink Europe’s R&D strategy for 2026: sustainability, regulatory compliance, responsiveness to graphical market trends, and customer-driven standardisation are the four pillars that will deliver purposeful, future-ready innovation.

Sustainable Innovation in Cold Transfer: Collaboration Between Toyo Ink Europe and KURZ

During Labelexpo 2025 in Barcelona, Toyo Ink Europe joined forces with KURZ to showcase a new standard in cold transfer applications for the label market.