Inside Toyo Ink Europe: Quality Control

The quality of our products is no coincidence – it is the result of precision, collaboration, and continuous improvement. Within Toyo Ink Europe, the Quality Control team plays a key role in this process. Thanks to Chi Yeung Lai, our QC Manager, we offer an exclusive look behind the scenes. Read on as he explains how every product is carefully checked and perfected step by step before it reaches the printing press.

From Order to Finished Product

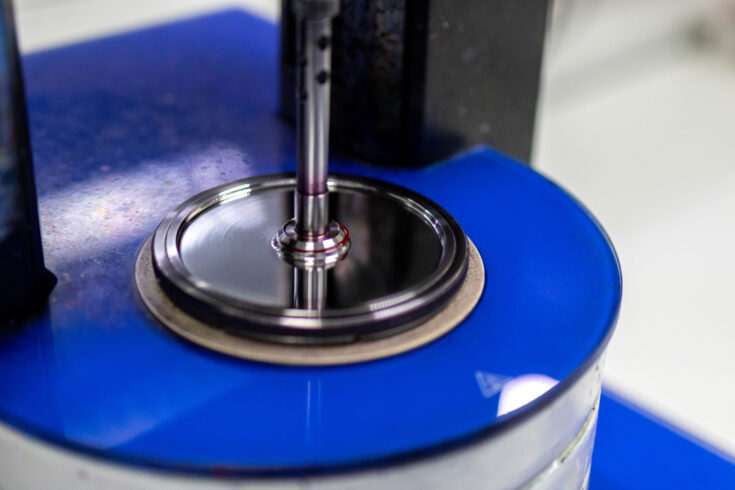

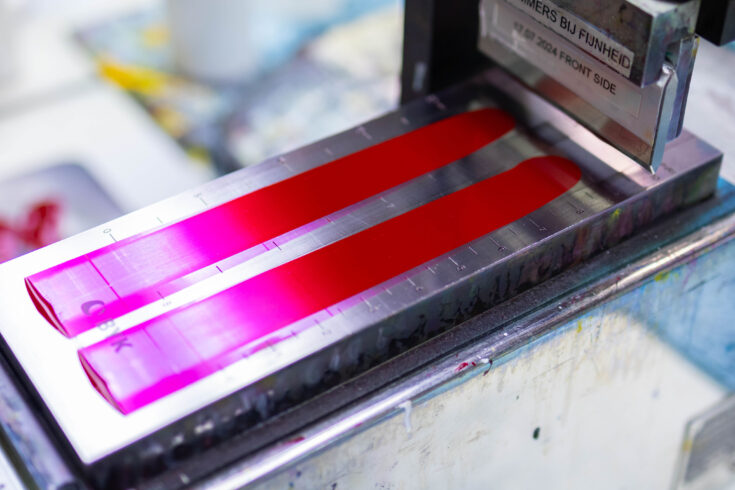

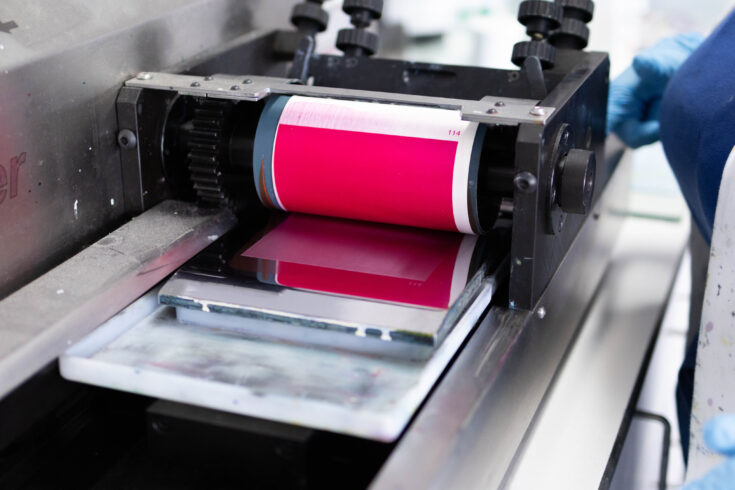

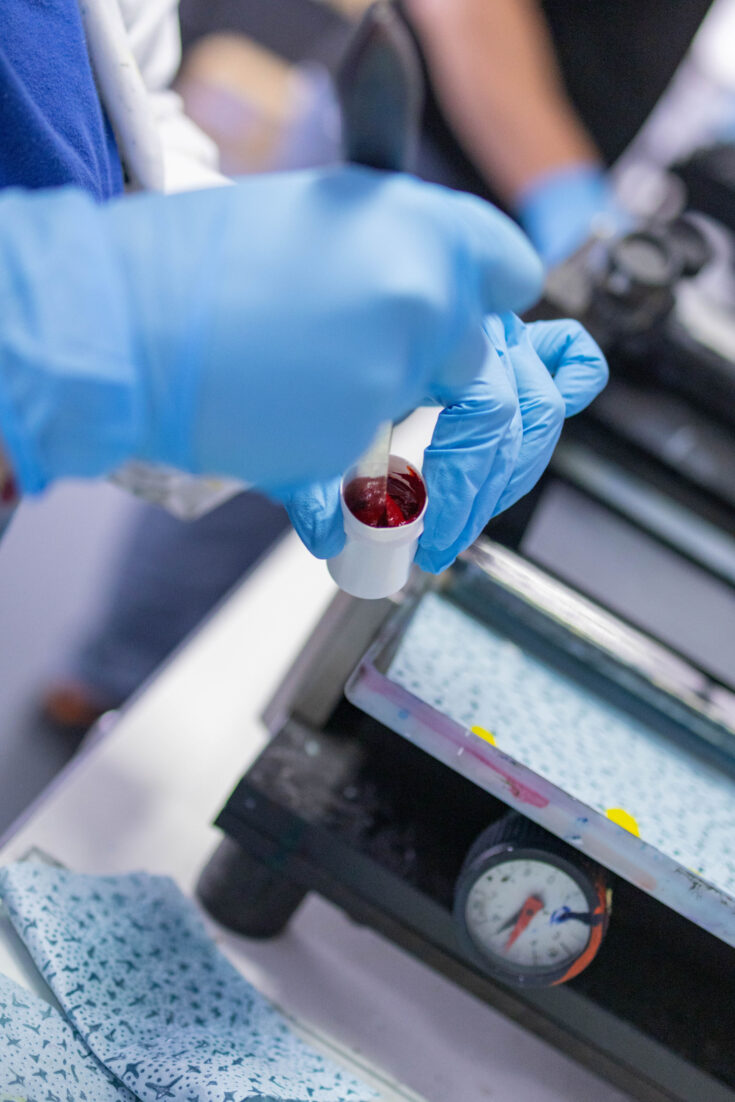

As soon as a production order comes in, the production process begins. First, a pre-mix is prepared which is carefully dosed and blended by the production department. This mixture is then transferred to our milling installations, where it is ground for the first time. After this initial milling, a sample is taken and sent to the QC laboratory, where it’s viscosity, fineness, and colour strength are analysed. If necessary, adjustments are made to the mixture.

Chi explains: “Once all parameters are within the required range, will we proceed to the next step and add the remaining additives. This is a deliberate choice, it helps us avoid contamination and optimize our process as much as possible.” After the final raw materials are added, another sample is taken and tested again for viscosity and colour strength, as well as for drying, flow, and colour tone. Corrections can then still be applied if needed.

“All results are recorded per batch in our ERP system, allowing us to generate a Certificate of Analysis (CoA) for each separate batch when requested by customers,” he continues. “For our inks intended for indirect food contact, we make an additional step: we take a sample that is screened for contamination by our analytical laboratory. This ensures optimal safety for every batch we produce.” Although it is rare for a batch to be rejected, at Toyo Ink Europe this never means waste. “All relevant departments are informed when a batch is rejected. It is then set aside so each team can assess how the product might be reused or improved.”

Strong and Interconnected Teams

Ensuring quality is not an isolated process. Within Toyo Ink Europe, Quality Control, Production, and Research & Development teams work closely together to continuously improve our operations. “During weekly meetings, we evaluate our processes. When production observes that too many adjustments are needed, this is logged. It gives us the opportunity to review and determine whether process modifications are required. We also discuss potential improvements,” Chi says.

He adds that complaints are systematically analysed to identify whether they result from inter-lot deviations. Whenever possible, preventive measures are implemented. “This approach allows us to grow continuously and take our quality to an even higher level.”

Raw Materials Up Close

Quality control is, of course, more than just internal products and processes. "Everything starts with our raw materials and their control," says Chi. Before raw materials are purchased from a particular supplier, they are first thoroughly screened by the purchasing and finance departments, among others. The RSSE (Regulatory, Safety, Sustainability and Environment) team then carries out a separate screening to verify quality, safety and regulatory requirements. Suppliers are also audited annually to ensure that they continue to meet our quality and sustainability standards.

Chi goes on to talk about the control of raw materials arriving at our production facility in Niel: "Incoming raw materials are strictly controlled. We examine the Certificate of Analysis (CoA) for each raw material and check whether it corresponds to reality. For critical raw materials, samples are taken and then checked for viscosity, temperature, colour and consistency with the previous batch from the same supplier, among other things. Some raw materials arrive in large quantities and are stored in bulk tanks. For these raw materials, in addition to the CoA, the cleaning certificate of the tanker is also thoroughly checked."

The Power of Collaboration

Quality is not a destination, but a continuous journey. Thanks to the expertise of our QC team and the close cooperation with Production, R&D, and all other departments, Toyo Ink Europe continues to build reliable, safe, and innovative products. Every batch, every drop tells a story of precision and dedication, clearly visible in the finished product.

Latest news

Toyo Ink Europe completed German Ink Ordinance compliant ink portfolio in 2025

Toyo Ink Europe, the European-based energy-curing inks division of artience Group, Japan, marked 2025 with a major expansion of its GIO-compliant ink portfolio.

Inside Toyo Ink Europe: Custom Colour Mixing

At Toyo Ink Europe, our colour mixing specialists work closely with customers, to ensure that every custom colour meets both visual expectations and technical requirements.

Toyo Ink Europe sets its R&D direction for 2026

Marc Heylen, General Manager Technology, explains Toyo Ink Europe’s R&D strategy for 2026: sustainability, regulatory compliance, responsiveness to graphical market trends, and customer-driven standardisation are the four pillars that will deliver purposeful, future-ready innovation.